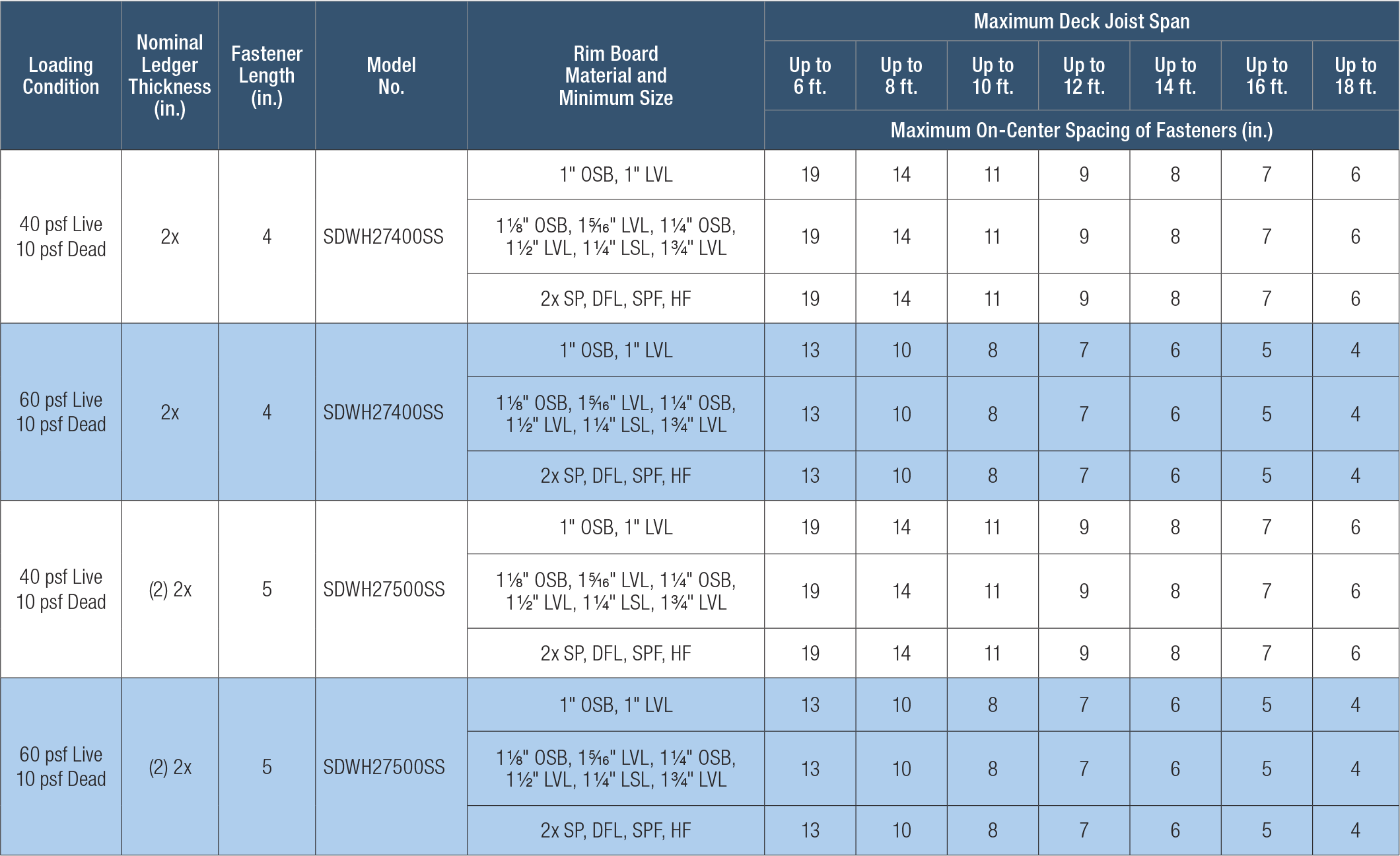

1. Screw spacing values are equivalent to 2024/2021/2018 IRC Table R507.9.1.3(1) and 2015 IRC Table R507.2. The table above also provides screw spacing for a wider range of materials commonly used for band joists, and an alternate loading condition as required by some jurisdictions.

2. Sawn rim board shall be spruce-pine-fir, hem-fir, Douglas fir–larch, or southern pine species. Ledger shall be hem-fir, Douglas fir–larch, or southern pine species.

3. Fastener spacings are based on the lesser of single fastener ICC-ES AC233 testing with a safety factor of 5.0 or ledger assembly testing with a factor of safety of 5.0. Spacing includes NDS wet service factor adjustment.

4. Multiple ledger plies shall be fastened together per code independent of the screws.

5. Screws shall be placed 1.5" to 2" from the top and bottom of the ledger or rim board with 3" minimum and 6" maximum vertical distance between fasteners with horizontal on-center spacing per the table. End screws shall be located 6" from the end and at 1.5" to 2" from the bottom of the ledger. For screws located at least 2" but less than 6" from the end, use 50% of the load per screw and 50% of the table spacing between the end screw and the adjacent screw, and for screws located between 2" and 4" from the end, predrill using a 5/32" drill bit for SDWH19SS and 7/32" drill bit for SDWH27SS.

6. Structural sheathing between the ledger and band shall be a maximum of 1/2" thick and fastened per code.

7. See Ledger-to-Rim Board Assembly image above.